Service

From expanding facilities to offering new services to collaborating on unique solutions, our focus at BNSF is always on finding ways to serve our customers reliably and consistently.

BNSF customers and local economic development organizations invested $1.2B in new or expanded facilities for the ninth consecutive year.

Results of 2019 Capital Investments

What We Carried in 2019

Total Units: 10,221

Y/Y change -4.5%

(Thousands of units, with year-over-year change)

Supporting Customer Growth

When our customers are ready to grow, BNSF is ready to meet their needs. In 2019 our customers and local economic development organizations collectively invested $1.2 billion to establish or expand rail-served facilities. This level of investment is expected to generate 2,000 new jobs.

2019 Customer Investment Highlights:

Ag Processing Inc. – A $300 million investment led to the opening of its 10th soybean processing location in Aberdeen, South Dakota. Ag Processing Inc.’s newest facility is expected to process more than 50 million bushels of soybeans annually and create 60 new jobs.

Hostess Brands, LLC – Located in Edgerton, Kansas, the new distribution center supports 200 new jobs. The $35 million investment strengthens the company’s distribution strategy with a direct connection to the nation’s supply chain through Logistics Park Kansas City.

SeaCa Packaging – A subsidiary of Seattle-Tacoma Box Company, the plastics manufacturer invested $18 million in opening its first plant location in Surprise, Arizona, creating boxes for agriculture products and gaining access to demand in the Southwest.

Adding BNSF Certified Sites

Through the BNSF Site Certification Program, BNSF selects strategically located sites across our network and prepares them for immediate customer development. This significantly streamlines the development of rail-served locations, saving customers six to nine months of construction time. In 2019, BNSF added eight new Certified Sites, bringing the total BNSF Certified Sites to 24.

New BNSF Certified Sites in 2019:

-

Becker Industrial Park in Becker, Minnesota

Adjacent to US Highway 10

67 acres available for development -

Clovis Industrial Park in Clovis, New Mexico

240 acres available for development

Located near BNSF Southern Transcon and highways 60, 70 and 84 -

Duane Michie Industrial Park in Hayti, Missouri

Half mile from Pemiscot County Port Authority

Close to two state highways and two interstate highways

250 acres available for development -

Elion Logistics Park 55 in Wilmington, Illinois

12 million square feet available for development

Access to BNSF Southern Transcon -

Lincoln Prairie South in Yorkville, Illinois

At intersections of state highways 34, 47, 71 and 126

Access to I-88, I-80 and I-55

220+ acres available for development -

Logistics Park Galesburg in Galesburg, Illinois

Along BNSF main line and I-74

300+ acres of shovel-ready land -

Railplex Industrial Park in Surprise, Arizona

292 acres available for development

Attracted more than $150 million in capital investment -

Springs Industrial Park in Holly Springs, Mississippi

North of Highway 22, 40 miles southeast of Memphis International Airport

1,200+ acres available for development

Maintenance Spotlight: Floating a Great Idea

In 2019, BNSF replaced two bridges on our Fallbridge Subdivision. The first one in North Bonneville, Washington, runs across Hamilton Creek. The second one in Home Valley, Washington, involved the use of a distinctive float-in, float-out method. After erecting a new 260-foot truss bridge on a barge 60 miles down the Columbia River in Portland, Oregon, we shipped the barge to Home Valley. We moved in another barge, ballasted by about 2 million pounds of water, under the existing bridge, slowly releasing water until the barge rose up and lifted the old bridge off its existing foundations. Then we moved the new bridge on its barge to the site of the new location. Using strand jacks, it was lowered onto its new foundations. This challenging feat of engineering resulted in a much lighter environmental footprint for the project, with far less impact on local marine life and fishing enterprises.

Maintaining and Expanding Our Network

We devote significant resources every year to make sure our network is optimized to meet our customers’ needs. Keeping the network well maintained limits the need for unscheduled service outages and maximizes the velocity and capacity we can deliver to customers.

BNSF invested $3.2B on maintenance and expansion of our core network.

Expanding and Adding New Facilities

BNSF is committed to growing with our customers, expanding as well as establishing new facilities for carload and intermodal customers to meet their growing capacity demands.

Logistics Center Hudson

In March 2019, BNSF broke ground on our new Logistics Center Hudson, which

will provide BNSF-rail-served sites that allow customers to reach Denver and

surrounding markets more easily. By investing directly in facilities in strategic

locations, BNSF helps customers save time and money in developing

rail-served facilities.

Logistics Center Hudson:

25 miles northeast of Denver International Airport

30 miles north of downtown Denver

430 acres

15 sites for customers who ship by the carload

Site for customers who ship by the trainload

Access to BNSF network

Access to I-76

Barstow Intermodal Facility

In July 2019, BNSF began eastbound and westbound service from our new Barstow Intermodal Facility, providing a new connection between Southern California and Chicago. The new premium container-only service unlocks additional capacity in this vital region, where transportation options are in extremely high demand.

Intermodal Facility Expansions

BNSF initiated a significant facility expansion project at our Alliance Intermodal Facility in Fort Worth, Texas. This multi-year project includes constructing new production tracks, increasing parking capacity and acquiring lift equipment. We also added more parking capacity at our Corwith Intermodal Facility in Chicago as well as our intermodal facilities in Denver, Phoenix and Portland, Oregon.

Expanding Service to the Ohio Valley

In 2019, BNSF added new service options for shippers between Southern California and the Ohio Valley region. These new services build on the popularity of recently introduced direct-rail intermodal service connecting Los Angeles, Stockton and the Ohio Valley region, providing our customers access to some of the fastest-growing industrial and consumer markets, including Toledo, Columbus, Cleveland, Cincinnati, Detroit, Louisville and Pittsburgh.

In 2019 BNSF:

Launched a new direct service between Stockton, California, and northwest Ohio.

Added Sunday morning eastbound service from our Los Angeles – Hobart facility to northwest Ohio.

Added a Monday morning westbound service from North Baltimore in northwest Ohio to Los Angeles – Hobart.

Responding to Record Flooding

Beginning in March 2019, BNSF dealt with the impact of months of record flooding in the Midwest. Service was affected in portions of South Dakota, Iowa, Nebraska and Missouri. At one point, nearly every section of our railway in the Northern Plains or Upper Midwest was either partially or fully out of service due to flooding.

Areas especially impacted were the Hannibal Subdivision in Missouri north of St. Louis, the River Subdivision in Missouri and the Napier Subdivision in Iowa and Missouri.

While transit times were unavoidably impacted due to washouts and high water, the people of BNSF, particularly our Engineering teams, along with our valued contractors, rose to the occasion of restoring service as quickly and safely as possible. BNSF teams worked round the clock to clear affected locations and repair damaged tracks.

Efforts included:

Re-routing trains wherever possible

Speed restrictions where necessary as areas came back into service

Ongoing track inspections by BNSF personnel

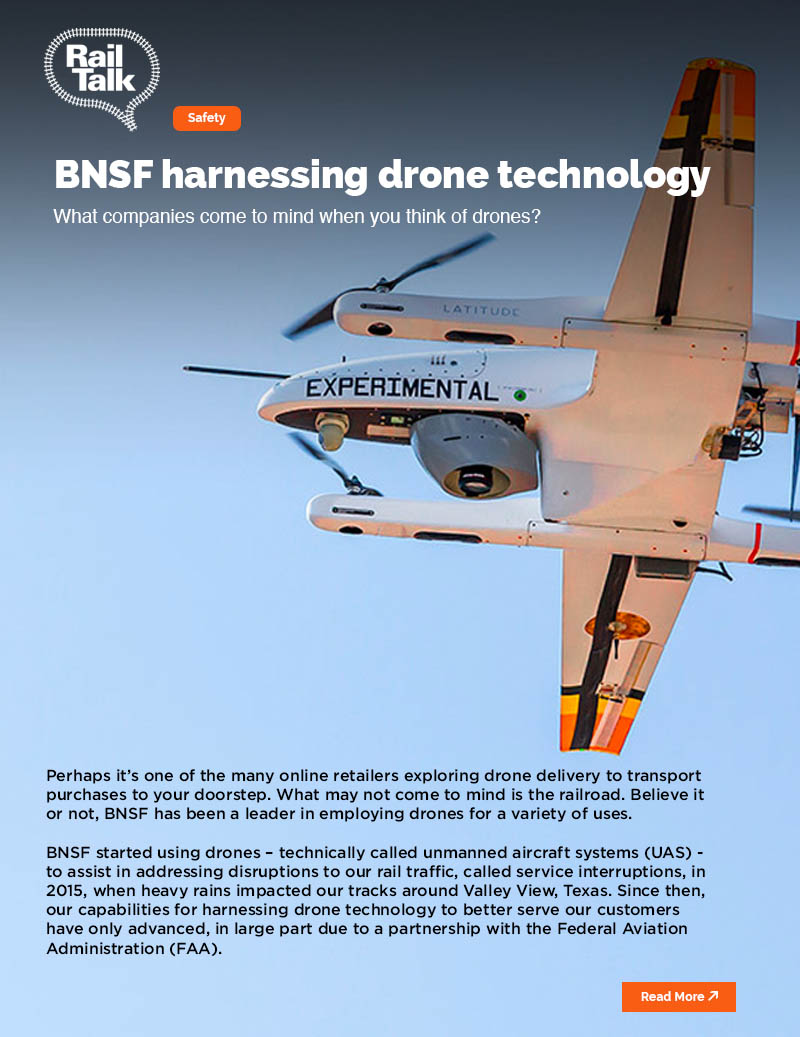

Use of drones to inspect areas unsafe for BNSF personnel

New 3,000-foot causeway constructed near Bartlett, Iowa

150+ route miles of track repaired and restored

2.2 million tons of material used to repair tracks

Unprecedented Midwest flooding caused new record river levels in 42 different locations.

Service Spotlight:

One Solution for Two Customers

One customer needed to get corn to chickens in Arizona. Another needed to get hay to cattle in Saudi Arabia. We served both with one facility, and we were able to keep the cows, the chickens and the customers satisfied. Working with Rose Acre Farms, an egg producer in western Arizona, and the shortline railway, the Arizona & California, BNSF developed an agricultural shuttle facility capable of delivering two 100-covered hopper shuttle trains of corn to the farm every month. We were then able to leverage the facility to also serve another customer, Fondamonte, to replace an over-the-road component in their shipping of nutrient-rich hay to Saudi Arabia via our international intermodal service.

Service Spotlight: Perfect Peak!

Did you get what you wanted last holiday season? There’s a good chance BNSF helped get it to you as we had a role in delivering more than 70 million packages. Indeed, the end of every year is our Peak Season, when we coordinate closely with package delivery companies to ensure items are delivered on time during this crucial period. In 2019, we delivered another Perfect Peak holiday shipping season, which means there were no service interruptions for one of the largest package delivery companies in the world!

Recognized Service Excellence

BNSF is committed to providing the highest level of customer service, and we are pleased when our customers recognize our excellence.

Customer recognition in 2019 included:

Railway Industrial Clearance Association awards for Clearance Group of the Year, Highest-Rated Railroad of the Year, Marketing Group of the Year and Highest-Rated Railroad for Operations/Transportation Performance

GoalZERO safety award from LyondellBasell

Toyota Logistics: President's Award for Rail Logistics Excellence – Best Railroad, fifth year in a row; Toyota Logistics Excellence Award for kaizen and customer service

Fiat Chrysler Automobile (FCA): FCA Logistics award; FCA Outstanding Railroad award

Honda: Origin-Loading Facility award; Destination-Loading Facility award

BNSF transported approximately 3.2M vehicles in 2019.

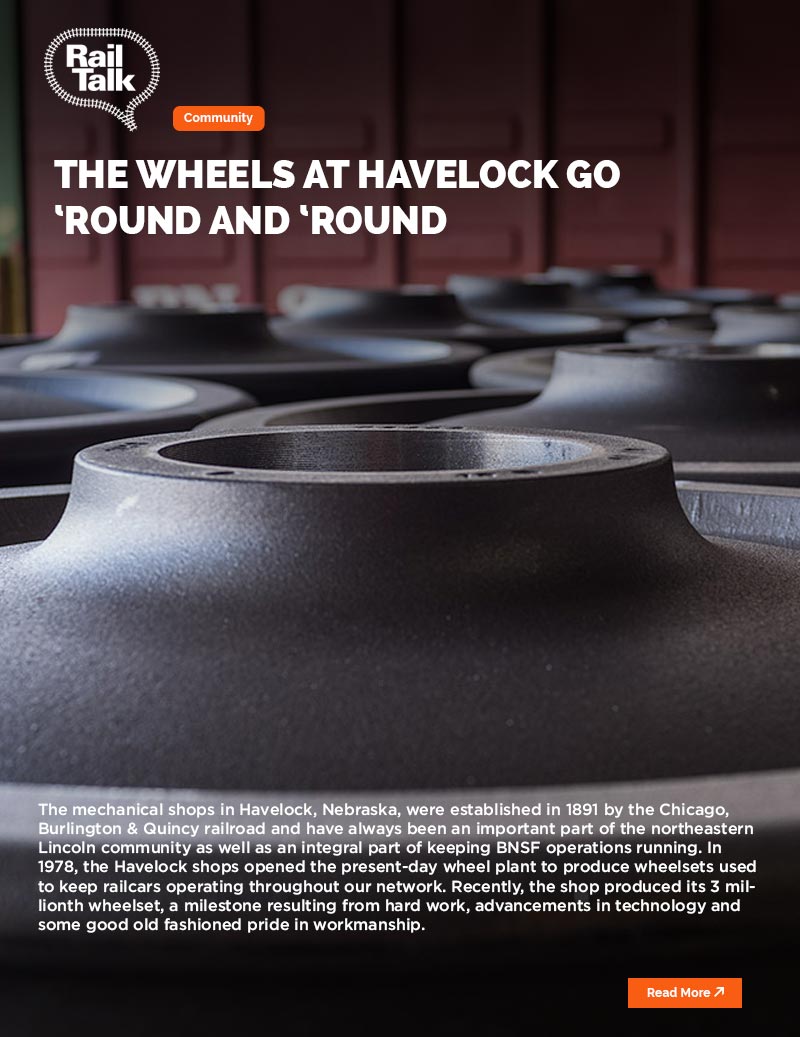

Wheeling Out a Milestone

About 90 percent of the wheels used on BNSF trains come from our Havelock Wheel Plant in Lincoln, Nebraska. We are the only U.S. Class I railroad that owns and operates our own wheel shop, the largest in the United States. In 2019, the facility, which opened in 1978, rolled out a major achievement: its 3 millionth wheel set!