On the roll again: Crews shut down BNSF’s Tulsa yard for resiliency upgrades, quickly resume service

By STEPHEN MANNING

Staff Writer

Sometimes, rail facilities must take a pause so the railroad can do crucial work to maintain safety on its infrastructure. Whether it's scheduled maintenance, repairs or upgrades to boost our capacity, it's all about serving our customers better for the long haul. Still, the shorter the interruption, the better.

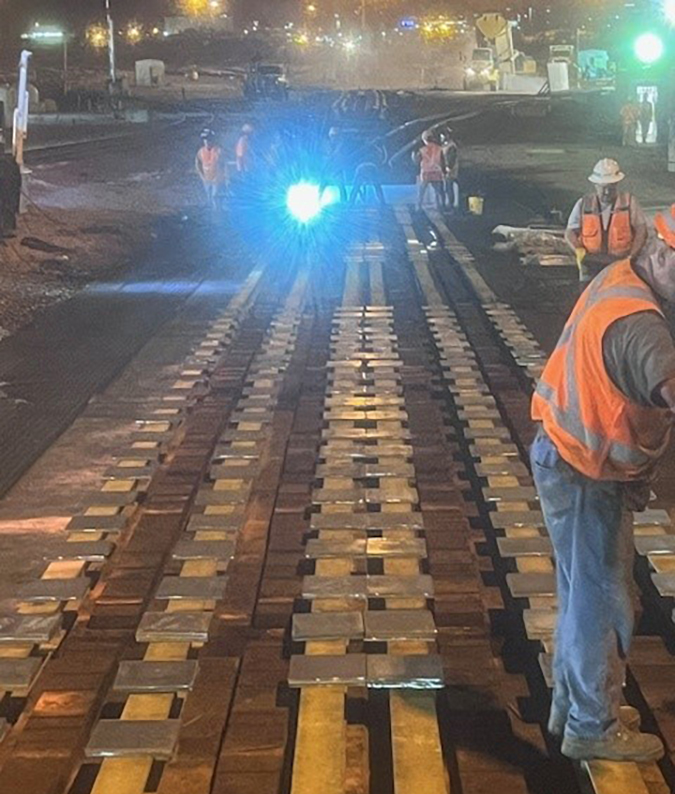

BNSF's Engineering Team recently had a challenge -- how to complete a significant list of upgrades at our Tulsa, Oklahoma hump yard while minimizing disruptions to our customers. These upgrades will enhance the reliability of our track and equipment at the yard.

A hump yard is a type of classification yard, where rail cars are sorted onto the correct trains to reach their destinations. A hump yard uses gravity to accomplish the sorting, with railcars rolling down an incline to connect to their train. These facilities are crucial for prompt and efficient movement of freight to the many destinations on our network.

For projects like this, crews are assigned a specific time window to complete the work, so trains can resume using the facility as soon as possible.

"For the Tulsa project, we answered a challenge to compress a large amount of reliability upgrades into a single week to minimize impact for our customers," said Matt Hammond, assistant vice president and chief engineer for BNSF’s South Region. "The original schedule tried to separate out the work to minimize the number of tracks impacted at a single time. As we continued planning the work, we learned it would actually be less impactful to completely shut down the yard for 48 hours, and then incrementally complete all the project work within 168 hours."

The yard was shut down on March 25 until the morning of March 27. During those 48 hours, rail cars carrying our customers' freight stayed on the move but were rerouted to other yards to be processed.

After the shutdown ended, the yard re-opened some tracks and resumed accepting rail cars for processing. Crews then worked on the remaining tracks and re-opened them one by one while the rest of the yard was operating, until all work was completed.

Tasks for the project included:

-

Building a new approach scale, used to weigh rail cars

-

Replacing the retarder and its foundation for Group 2 tracks. Retarders safely control the speed of rail cars as they roll down the hump to be sorted.

-

Adapting the master retarder foundation and replacing the master retarder. The master retarder is the first retarder rail cars pass through as they enter the hump.

-

Installing 9 NX power switches, which enable a yard operator to remotely or locally control signals and switches from a central location

-

Adding skate retarders, which safely stop rail cars and keep them within the hump yard

-

Completing track maintenance repairs to enhance reliability, including installing 10,000 feet of track and surfacing 5,000 feet of track

The project involved our Signal, Track, Structures, Operating and Service Design teams. After a few months of planning, approximately 140 people completed the work. All teams involved had representatives on site throughout the work.

Signal Director Corey Stethem said the project stayed on schedule, with the crews responding swiftly to issues that came up.

“Overall the project went very smoothly,” Stethem said. “We encountered a few obstacles we had to overcome, and we did. With proper planning, we completed the work with no injuries or accidents. The most successful thing we did was that everyone got to home safely at the end of the day.”

Now an enhanced railyard is fully operational at Tulsa, ready to serve our customers even better.

“I am extremely proud of the professional railroaders who came together to plan and execute this historic project,” Hammond said. “The work was completed safely and ahead of schedule. My thanks to all the employees who worked diligently to make this happen.”