No tracks? No problem—that’s why we have transload

It’s hard to imagine moving a freight car from where its journey starts and where it ends without railroad tracks at either point. But at BNSF that’s no problem, and not just for customers moving one freight car but for multiple cars, thanks to a service called transloading.

Like the name suggests, transloading is a logistics solution that combines rail and trucking/barge/ship. When a shipper, for example, a beverage company in Colorado, wants to move pallets of product thousands of miles away, but the receiver doesn’t have their own tracks, they can utilize a third-party transload facility with tracks close to the destination. From there, the loads can be transferred from the railcar, in this case a boxcar, then trucked to the receiver.

The reverse also applies. If the shipper doesn’t have a rail-served plant, but the receiver does, a shipper can truck from their facility to a third-party transload, which will load the railcar and ship it to the receiver. Another scenario is both the shipper and receiver are not rail-served. A transload on the shipper side and another on the receiver side can be utilized to ship goods, proving that not having a rail-served facility is no reason to not move by rail.

Why would a shipper want to add in these incremental steps instead of transporting the entire trip via truck? In a word: Cost.

Shipping by rail not only offers shippers an economic advantage, it also gives them flexibility and an opportunity to expand their business and market reach. They’ll also be reducing their carbon footprint. Thanks to the fuel efficiencies of rail, we can move one ton of freight nearly 500 miles on one gallon of diesel fuel.

Like our intermodal customers who have long recognized the advantages of combining rail with truck, our other customers whose freight moves in a railcar other than a container or trailer – like a boxcar, tank car, hopper, flat car and more -- can realize the same benefits.

“Thanks to our large transload network, we can handle multiple commodities, from the food we eat to fuels like diesel and gasoline we use -- and much, much more,” Matt Buckwalter, senior manager, Economic Development at BNSF, said.

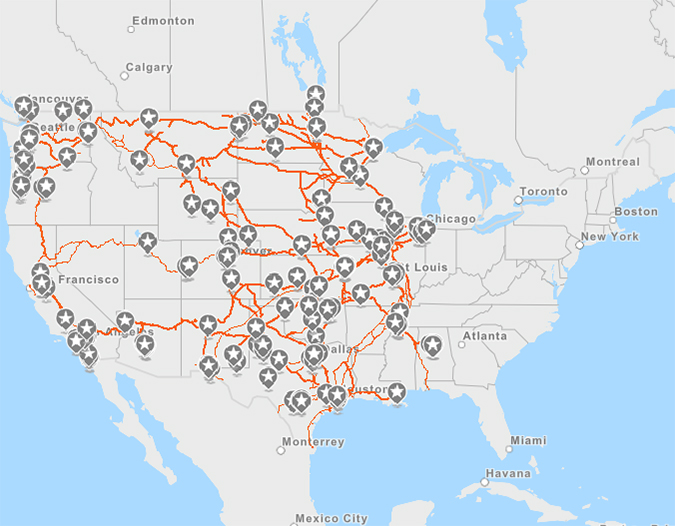

This BNSF transload network has access to about 450 transloading facilities and relies on 190 selected premier transloaders. A BNSF premier transloader is a distinguishment for our transloaders who meet certain criteria outlined by BNSF, including safety records. They are strategically located at points where our railroad lines intersect with highway systems and have the infrastructure needed to facilitate the transfer of goods.

One of our longtime premier transloaders is Springfield Underground based out of Springfield, Missouri. Just one example of what and how this company transloads is the salt needed by local cities for clearing roads during winter. They unload salt from railcars using a bulk material conveyor, then truck the product to destination. The same process is also used to move plastic pellets used in the manufacturing or conduit, water pipe and fiber innerduct.

“Working with BNSF, our goal is to find customers who don’t know about rail and the substantial environmental and economic impacts of moving long-haul freight by rail,” Springfield Underground CEO John Griesemer said. “Our team pieces together the steps to get manufacturers’ raw materials from origin to manufacturing destination. Once a client is committed to rail, we work hard to improve our services, continuously checking on how we’re doing and adjusting to ensure the client remains committed to rail and transloading as part of their supply chain.”

Hallett Railroad Storage & Services (HRSS), a premier transloader in Duluth, Minnesota, with connections to rail, highway and water, daily keeps the lines of communication open with BNSF to make sure together we’re providing reliable and quality service.

“Every morning, we call the local BNSF yardmaster to make sure we have a clear plan for service for the day. In conjunction with these conversations, we also access BNSF’s portal to keep track of all incoming and released cars,” HRSS President Jeff Heller explained. “Our relationship is also strengthened by our staff attending BNSF’s annual transload conference. Through these meetings and networking, we’re working cooperatively to mitigate operational issues.”

Another premier transloader is Plastic Express with several locations across BNSF. Thanks to their ongoing collaboration with BNSF, Plastic Express has expanded into new markets, improved their service, capacities and capabilities – and grown business. Initially the company handled materials for the plastics industry but has now expanded to steel, paper, lumber and other industrial and consumer products.

“We see ourselves as an extension of BNSF, reaching markets or facilities with limited rail access,” Plastics Express Chief Marketing Officer Jennifer Pittman Fussell said. “We recognize the importance and take pride in serving the first and last mile of product shipments, which typically incorporate storage, packing, inventory management and safe and timely reception and delivery. Our model, along with strong business relationships and customer-focus culture, has expanded our footprint with BNSF by 15% in just the past two years.”

These transloaders and others have the equipment, facilities and people needed to safely and securely transfer freight between modes. Equipment for transfer might be forklifts, conveyor belts, portable ramps or hoses. In addition, transloaders can provide a range of services, from onsite storage, including cold storage, to cross-docking and load consolidation.

Buckwalter said shippers interested in using transload services are those looking to reduce their transportation costs or avoid having to spend capital to build rail into their facility, as well as those shipping goods and materials more than 500 miles away.

“Our transloaders can handle about any commodity and we see this service as something that will only grow,” Buckwalter added. “We’re collaborating with our preferred transload providers to be sure we and they have the services our customers need to realize the best that rail can provide.”

Learn more about BNSF’s transload services here or watch this video about how the service works.

Did You Know?

Among the types of facilities in BNSF’s transload network are those that can handle dimensional, warehouse or bulk commodities – or a combination:

- Dimensional (long or heavy) loads, like lumber, steel and machinery can be transferred from or to railcars like flatcars, gondolas and centerbeam cars.

- Warehouse facilities provide a building with rail-unloading capabilities and specialize in products shipped in boxcars.

- Bulk facilities are where dry and liquid products can be transferred from covered hopper or tank cars, like plastic pellets, flour, cement, acids and ethanol.